H Type Layer Cage

Technical Description

Ⅰ.Cage and Frame System

Main frame structure of the equipment with reasonable design, durability, no deformation, stability is made of hot-dip galvanized steel plate;

The sliding cage door of layer cage is semi-open or fully-open designed for easy management;

Plastic parts are used for limitation, making operation convenient and avoiding birds escape;

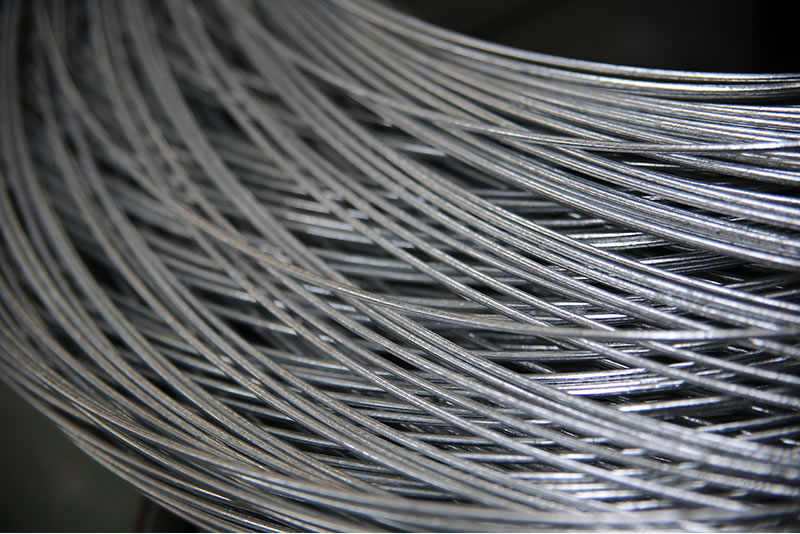

Hot-dip galvanized or Al-zinc coating cage mesh makes sure the long service life of the equipment;

Reasonable Angle of bottom net ensures that eggs roll onto the egg belt smoothly, effectively reduce the rate of egg damage;

The side cage mesh is connected with steel wire which can strengthen the air convection to ensure the ventilation of the house and reduce the temperature of chicken;

The equipment is easy to clean, which can offer a comfortable living environment for chicken;

High precision numerical control machine is utilized for positioning cutting.

Ⅱ. Automatic Feeding System

V-shaped rolled feed trough has high structural strength and wide section, saving feed, preventing feed from throwing and mildew which improves feed conversion rate;

The structure is simple and the maintenance is convenient;

The feed is evenly distributed and the feed volume is large;

Clients also can choose Chain feeding type according to their different feeding requirements.

Ⅲ.Automatic Drinking System

The front-end filter unit ensures clean water, with 2 nipples in a single cage, sufficient water supply and convenience in drinking.

A V-shaped water trough is arranged under the drinking line to prevent water drops from falling on the manure belt and water content of birds manure is low;

Patented drinking tap.

Ⅳ.Automatic Manure Removal System

The manure cleaning system features high resistance to corrosion and reasonable structural design, ensuring that the manure belt is clean.

Polypropylene(PP)manure belts are located underneath the chicken cage to collect manure. Manure can be stored and ventilated on the conveyor belt for a period of days. When removing manure,the manure falls from each tier of manure belt onto the horizontal manure belt.Then it can be transported to the manure storage room or be transported to manure truck through the syncline manure belt.

Ⅴ.Automatic Egg Collection System

The egg collection system features stable operation, low egg breaking rate, convenient operation and high automation;

Polypropylene tape is the most flexible and adaptable egg collection channel. With the tension device of the egg belt and the flexible egg blocking system, It can effectively ensures that the eggs roll onto the egg collection channel safely and minimize the breakage rate of eggs;

Egg collection machine uses the brush to remove dirty trashes and maintain clean machine;

Adopting new type C eggs claws and realize a smooth transition, collect the egg effectively prevent the egg from broken.

Ⅵ.Automatic Control Panels System

The climate control system is highly automated and intelligent, providing a good living environment for birds which can reduce mortality rate of birds and enhance laying rate;

Intensive management and fully automatic control system realize feeding、drinking、 manure cleaning、 environmental control and egg collecting automatically which improve the rate of labor productivity and save the labor cost.

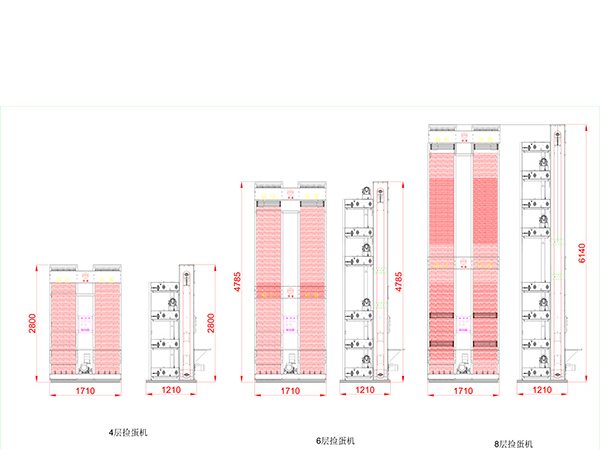

Product Parameters

| No. of tier | average area/bird(cm2) | birds/cage | tier distance(mm) | cage length(mm) | cage width(mm) | cage height(mm) |

| 4 | 450 | 8 | 680 | 600 | 600 | 510 |

| 6 | 450 | 8 | 680 | 600 | 600 | 510 |

| 8 | 450 | 8 | 680 | 600 | 600 | 510 |

Product Display